Introduction to EDEM

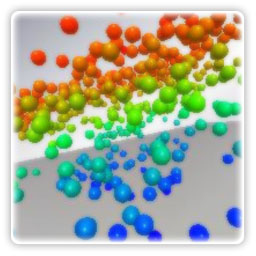

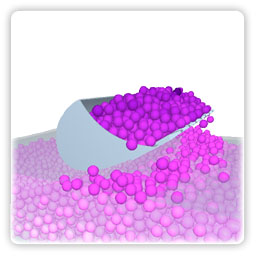

DEM Solutions is a UK based company which created advanced Discrete Element Method (DEM) software called EDEM. This powerful tool allows users to simulate, analyse and visualise the behaviour of particles so it is possible to obtain high quality information on particle kinematics, momentum, heat and mass transfer. [11]

Since its launch in 2005, EDEM has been successfully used in many different sectors including:

- Pharmaceutical

- Chemical

- Mineral

- Materials processing

- Mining

- Oil & gas production

- Geo-mechanics

- Agriculture

- Construction and Geotechnical Engineering

Furthermore, EDEM has even been used in space exploration! The long story short, DEM Solutions was asked by NASA to use their software to analyse the behaviour of the dust covering the moon. This is not just ordinary dust: it is made of charged particles that tend to stick to anything displaying an opposite polarity, such as parts of space modules, equipment and even spacesuits, causing lots of problems. Knowledge of the particle behaviour and simulations of the formation and settlement of dust, will allow NASA either to modify the design or create some form of shielding. [12]

These industries are dealing with complex manufacturing processes of the high value. EDEM allows for designing, developing and testing of products and processes faster, more accurately, efficient and without the need to build costly prototypes.

Key Features of EDEM

One of the key features of EDEM is its ability to model both particles and equipment. Therefore it provides information which can be successfully used for investigating the relative effect of particle material properties, environmental conditions and equipment design. As a result it allows creating more accurate simulations.

Another very useful aspect of software is its CAD compatibility which simply means that CAD models or real particles can be imported into the software. Users are able to create particles it their accurate size and shape. Afterwards mechanical and material properties can be added or copied from previously created material or particle libraries and as a result complete model particle is generated. Geometry of machine can be imported from CAD or CAE systems as solid models or meshes.

EDEM can also be couple directly with:

- CFD (Computational Fluid Dynamics) to model solid-fluid phase systems at the particle scale – systems where particle-particle and particle-wall interaction is critical to system behaviour and

- FEA (Finite Element Analysis) to simulate dynamic loadings on machine components

Computational Fluid Dynamics and Finite Element Analysis are the best known for structural analysis and simulation of fluid flow/heat transfer respectively. DEM Solutions is using DEM in conjunction with CFD and FEA to provide a much more accurate picture of a product's performance. [13]

» Next: Analysis